Key Features

- Perfect for heavy soils, residue sizing/incorporation

- Five widths from 23'7" to 40'8"

- Easy-to-tension 2-in. gang bolts

- Hydraulic fore/aft leveling

Features

Ground-engaging components on 2623

Ground-engaging components on 2623 Three-section disk in transport

Three-section disk in transportThe John Deere 2600 Series offer three disk models that provide a wide range of variety for all tillage applications.

Model | 2620 Disk | 2623 Disk | 2625 Disk |

| Purpose | Secondary (light duty) | Dual purpose (medium duty) | Primary (heavy duty) |

| Working depth (mm, in.) | Up to 130 mm (5 in.) | Up to 180 mm (7 in.) | Up to 200 mm (8 in.) |

| Weight per blade (kg, lb) | Minimum 68 kg (150 lb) | Under 13.4 m (44 ft) Minimum 86 kg (190 lb) Over 13.4 m (44 ft) Minimum 91 kg (200 lb) | Minimum 127 kg (280 lb) |

| Blade size (mm, in.) | 560 or 610 mm (22 in. or 24 in.) | 610 or 660 mm (24 in. or 26 in.) | 610 or 660 mm (24 in. or 26 in.) |

| Blade spacing (mm, in.) | 185 or 230 mm (7.25 in. or 9 in.) | 230 mm (9 in.) | 230 mm (9 in.) (front) and 280 mm (11 in.) (rear), or 280 mm (11 in.) |

| Horsepower (hp/m, hp/ft) | 23 - 36 m/hp (7 - 11 ft/hp) | 23 - 36 m/hp (7 - 11 ft/hp) | 26 - 36 m/hp (8 - 11 ft/hp) |

| Working widths (m, ft) | 6.3 m - 15.0 m (20.75 ft - 49.25 ft) | 6.3 m - 15.0 m (20.75 ft - 49.25 ft | 7.2 m-12.4 m (23.58 - 40.66 ft) |

| Operating speed (km/h, mph | 6.5 - 11.3 km/h (4 - 7 mph) | 6.5 - 11.3 km/h (4 - 7 mph) | 6.5 - 11.3 km/h (4 - 7 mph) |

| Recommended use |

|

|

|

John Deere's 2600 Series Disks offer different blade options for soil penetration and residue sizing.

Cone blade

Cone blade Solid-spherical blade

Solid-spherical blade Cutout-spherical blade

Cutout-spherical blade| Blade type | Cone blades (John Deere exclusive) | Solid-spherical blades | Cutout-spherical blades |

| Recommended application |

|

|

|

| Recommended soil type | Heavy soils | Light to medium soils | Heavy to medium soils |

| Benefits | Move soil and reside freely, but also increase draft requirements | Better control of soil than cone blades since less sensitive to over speeding | Chopping or trapping residue |

| Penetration | Penetrate well at a 20-degree gang angle, but best at a 22-degree gang angle | Penetrate best at a 20-degree gang angle | Penetration is excellent with a cutout blade |

NOTE: Cone blades not recommended in rocky conditions.

Disk blade options

- Disk blades compatible with 2620 Disk

- Disk blades compatible with 2623 Disk

- Disk blades compatible with 2625 Disk

The 2625 General-Purpose Disk comes equipped with front and rear solid-spherical disk blades with

280-mm (11-in.) spacing. The primary blade size is 610 mm (24 in.) x 6.5 mm (0.256 in.)

Additional blade options for the 2625 are listed below.

230-mm (9-in.) disk spacing

230-mm (9-in.) disk spacing 280-mm (11-in.) disk spacing

280-mm (11-in.) disk spacing280-mm (11-in.) spacing, front and rear

- Excels in high residue conditions where residue flow may cause plugging on narrower spacing

Allows for more weight to be transferred per blade which increases penetration in heavy soils

230-mm (9-in.) front spacing/280-mm (11-in.) rear spacing

- Works well in primary tillage in all soil types

- Provides excellent residue sizing capability with 230-mm (9-in.) spacing on the front gang

Allows for increased residue handling capabilities with 280-mm (11-in.) rear gang spacing

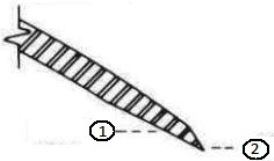

NOTE:

- The number 1 edge has a beefier profile and is best for rocky conditions.

- The number 10 edge has a narrower profile and should work well in most non-rock conditions.

- Rear main and wing gangs are tapered with one blade 51 mm (2 in.) smaller than the primary blade.

- Integral furrow filler blades are included with all rear wing gangs which are 102 mm (4 in.) smaller than the primary blade.

- Front outer gangs have a taper that is 51 mm (2 in.) smaller than the primary blade, except for 560-mm (22-in.) disk blades.

Number 1 edge (outside bevel, outside grind)

Number 1 edge (outside bevel, outside grind) Number 10 edge (inside bevel, outside grind)

Number 10 edge (inside bevel, outside grind)- Bevel

- Grind

50-mm (2-in.) disk gang bolts

50-mm (2-in.) disk gang bolts Gang tension system

Gang tension systemJohn Deere's 2600 Series Disks provide an innovative approach to tension disk gang bolts.

Hydraulic fore-aft leveling

Hydraulic fore-aft levelingHydraulic fore-aft leveling comes as standard equipment with John Deere's 2600 Series Disks. Operators can level the disk from the comfort of the tractor cab.

Sealed maintenance-free bearings (front view)

Sealed maintenance-free bearings (front view) Sealed maintenance-free bearings (bottom view)

Sealed maintenance-free bearings (bottom view)John Deere’s 2600 Series Disks feature a sealed maintenance-free bearing. A high-density polymer liner allows the bearing to dynamically align the shaft in rough field conditions. The bearing and high-density polymer liner sit inside cast housing. This cast housing was designed for strength and reliability as well as a built-in bearing wear guard.

These bearings increase productivity by reducing the amount of time needed to service the disk before operation and allowing customers to spend more time in the field.

Residue management

Residue managementAs crop yields increase, so does the amount of residue after harvest. The John Deere 2625 Disk gives operators a primary disk option that has up to 300 lb/blade to size and bury residue in the toughest residue and field conditions.

Utilize the residue calculator to identity the optimal residue management solution to meet the operator’s needs.

Key Specs

| Working width | 9.35 m 30.67 ft |

| Transport width | 4.7 m 15.5 ft |

| Transport height | 3.96 m 13 ft |

| Working depth | Up to 20.3 cm 8 in. |

| Blade spacing | Option 1: front and rear spacing both: 27.9 cm 11 in. Option 2: front spacing: 22.9 cm 9 in. and rear spacing: 27.9 cm |

| Horsepower per ft | 6.7 to 8.2 kW 9 to 11 hp |

| Operating speed | 8.05 to 11.3 km/h 5 to 7 mph |

Machine

| Working width | 9.35 m 30.67 ft |

| Transport width | 4.7 m 15.5 ft |

| Transport height | 3.96 m 13 ft |

| Gang standards | C-spring |

| Gang angle | 21/19 degree (angle) |

| Purpose | Primary |

| Working depth | Up to 20.3 cm 8 in. |

| Weight per blade | 127.9 kg 282 lb |

| Blade size | 60.96 cm 24 in. 66.04 cm 26 in. |

| Blade spacing | Option 1: front and rear spacing both: 27.9 cm 11 in. Option 2: front spacing: 22.9 cm 9 in. and rear spacing: 27.9 cm |

| Horsepower per ft | 6.7 to 8.2 kW 9 to 11 hp |

| Operating speed | 8.05 to 11.3 km/h 5 to 7 mph |

| Blade concavity | |

| Blade thickness |

Number of blades

| Front blades | Option 1: 34 with front and rear spacing both: 280 mm 11 in. Option 2: 37 with front spacing of 230 mm 9 in. and rear spacing of 280 mm |

| Rear blades | Option 1: 34 with front and rear spacing both: 280 mm 11 in. Option 2: 37 with front spacing of: 230 mm 9 in. and rear spacing of: 280 mm |

| Total | Option 1: 68 with front and rear spacing both; 280 mm 11 in. Option 2: 74 with front spacing of: 230 mm 9 in. and rear spacing of: 280 mm |

Number of C-Springs

| Main frame front | Option 1: 6 with spacing of 280 mm 11 in. Option 2: 6 with front spacing of 230 mm 9 in. and rear spacing 280 mm |

| Main frame rear | Option 1: 4 with spacing of 280 mm 11 in. Option 2: 4 with spacing of 230 mm 9 in. and rear spacing of 280 mm |

| 1st wing front | Option 1: 6 with spacing of 280 mm 11 in. Option 2: 6 with front spacing of 230 mm 9 in. and rear spacing of 280 mm |

| 1st wing rear | Option 1: 6 with spacing of 280 mm 11 in. Option 2: 8 with front spacing of 230 mm 9 in. and rear spacing of 280 mm |

| 2nd wing front | |

| 2nd wing rear | |

| Total | Option 1: 22 with spacing of 280 mm 11 in. Option 2: 24 with spacing of 230 mm 9 in. and rear spacing of 280 mm |

Additional information

| Date collected |