Key Features

- Superior strength and visibility

- For heavy-duty chores

- Parking stands are integrated on the loader

Features

Single-point hydraulic connection

Single-point hydraulic connection

Operating the hydraulic pressure relief knob

Operating the hydraulic pressure relief knob

The H480 Loader features a single-point hydraulic connection that also incorporates the connection point for any electrical needs and the ability to relieve hydraulic pressure. In order to disconnect the hydraulic connection between the loader and the tractor, it has always been necessary to relieve the hydraulic system oil pressure. This has sometimes been difficult to accomplish and is also the reason why a coupling system was not offered on some tractors.

Now the ability to relieve the hydraulic oil system pressure is included with the single-point hydraulic connection, which allows for easily disconnecting both hydraulic and electrical lines to the loader from a convenient location with virtually no oil loss.

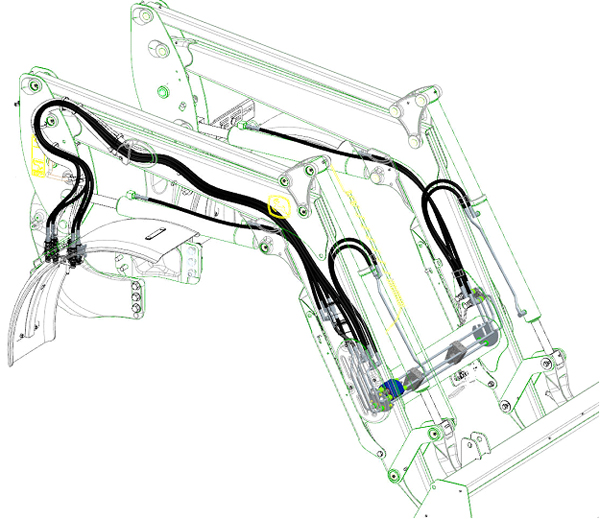

Concealed oil lines through boom arm

Concealed oil lines through boom arm

Oil lines routed through the boom arm

Oil lines routed through the boom arm

Oil lines routed through the torque tube

Oil lines routed through the torque tube

Over time, increased width in tractor hoods have caused issues with available space for running traditional oil lines of a loader along the boom, making them more susceptible to damage.

To improve this situation, the oil lines have been routed through the boom arm and the torque tube, improving line protection and the appearance of the loader.

Parking stands

Parking stands

John Deere loaders are easily removed and reinstalled on tractors without tools. The parking system allows removing or attaching the loader to the tractor in minutes without the need for tools.

In order to remove or park the loader, apply slight down pressure to the loader boom with the bucket dumped at approximately a 30-degree angle. With the tractor in park, install the parking stands and place the mast pins in the open position.

Removing or parking the loader

Bucket slightly dumped and down pressure

Bucket slightly dumped and down pressure

Parking stand in stored position

Parking stand in stored position

Removing parking stand

Removing parking stand

Bucket slightly dumped - Parking stands installed

Bucket slightly dumped - Parking stands installed

Mast pin in the closed position

Mast pin in the closed position

Mast pin in the open position

Mast pin in the open position

Utilizing the boom circuit with the tractor in neutral, rotate the mast forward until the mast has rotated past the pin location on the mounting frame by extending the lift cylinder. Now using the bucket circuit, rollback the bucket until the mast is removed from the pocket and will clear the tires.

Masts rotated forward, then bucket rolled back

Masts rotated forward, then bucket rolled back

With the tractor in park, shut the engine off and relieve the hydraulic pressure as indicated for the tractor. Relieve pressure on the single-point hydraulic connection, then disconnect or open the single-point hydraulic connector.

Relieving the hydraulic pressure

Relieving the hydraulic pressure

Disconnect/open single point hydraulic connection

Disconnect/open single point hydraulic connection

Store the loader half of the single-point connector. The tractor is now ready to back away from the loader.

Storing the hydraulic hoses

Storing the hydraulic hoses

Tractor ready to be backed away from loader

Tractor ready to be backed away from loader

Backing away from loader

Backing away from loader

Parked loader

Parked loader

Hydraulic shut-off valve (open position)

Hydraulic shut-off valve (open position)

Hydraulic shut-off valve (closed position)

Hydraulic shut-off valve (closed position)

A hydraulic shut-off valve is included with the H-Series Ag Loaders to ensure the loader does not lower suddenly. For example, this allows the boom to be locked out when someone is required to be located under the loader boom for service work on the tractor. It should not be used for extended periods of time unless an appropriate support stand is also utilized.

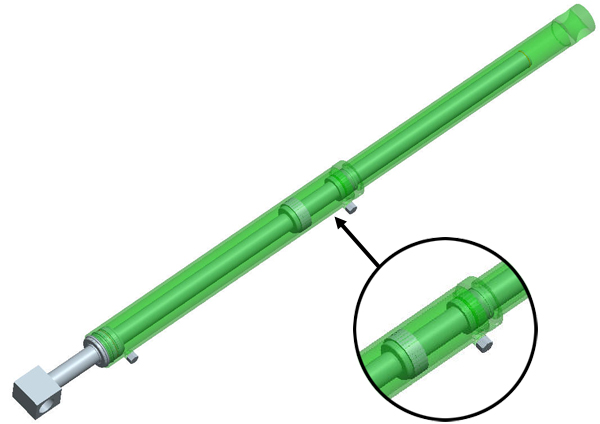

False rod cylinder

False rod cylinder

Fast bucket cycle times are important to dump the load from the bucket as quickly as possible, in order to be as productive as possible, while completing loading operations. The bucket cylinder design can have a major impact on this cycle time, especially for the mechanical self-leveling (MSL) loaders.

Therefore, all MSL M- and H-Series Loaders utilize false rod bucket cylinders. A false rod cylinder has a smaller displacement of oil requirement on the head end of the cylinder, which allows this cylinder to dump much faster than a normal cylinder.

The electric remote carrier latching system provides enhanced productivity and improved operator comfort when changing loader attachments. This time-saving feature allows an operator to unlatch and latch attachments for Global or Global Category 2 Carriers without leaving the operator's station.

Electric remote carrier latching system on H340 Loader

Electric remote carrier latching system on H340 Loader

Unlike competitive remote latching systems, the John Deere electric remote carrier latching system utilizes a simple electric actuator instead of third function hydraulics and/or diverter valves for the loader.

Nitrogen-charged accumulator and electric valve

Nitrogen-charged accumulator and electric valve

Loader suspension and electric remote carrier latch rocker switch panel

Loader suspension and electric remote carrier latch rocker switch panel

A feature intended to improve loader productivity, the LSS allows the boom cylinders to float,

reducing the jarring effects loads are prone to over rough terrain.

- An accumulator charged with nitrogen and connected to the head-end lift cylinder hose through a T-fitting provides shock absorption

- The cylinders move in and out to allow the boom to float

- Bales can be transported more efficiently from one end of the field to the other over frozen, hard-packed, or rutted terrain

- Pallets can be moved easily without sustaining cargo damage

- Pallets of seed or fertilizer can be carried across a yard without a bag spilling and creating a costly mess

- Extended life of loader pins and bushings

- Less stress on the tractor axle

- Properly ballasted tractor with LSS has increased stability, creating a smoother ride for the operator

Reasons for turning LSS off include:

- Digging applications- with LSS on, the cylinders retract slightly, losing lifting power

- Holding a grade when blading – with LSS on, it is difficult to hold a constant grade

- Precise pallet and bale handling – with LSS on, the load moves up and down slightly while being positioned

- Parking a loader – with LSS on, when down-pressure is applied, the lift cylinders retract slightly, making it more difficult to park

The loader suspension system is controlled by a switch conveniently located in the operator station so it can be easily reached for activation or deactivation as needed.

Key Specs

| Maximum lift height (A) | 4650 mm 183.1 in. |

| Lift capacity at full height | Measured at pivot (U) 2065 kg 4553 lb |

| Boom breakout force | Measured at pivot (Y) 4793 kgf 10567 lbf |

| Bucket rollback force capacity | At ground-level line (ZZ) 4640 kgf 10229 lbf |

| Clearance at full height - bucket dumped (C) | 3820 mm 150.4 in. |

| Dump angle, degrees (E) | -58.9 degree (angle) |

| Rollback angle, degrees (G) | 42 degree (angle) |

Tractor

| Model | 7820/7830 |

| Front tire | 380/85R34 |

| Rear tire | 480/80R46 |

| Front axle configuration | |

| Wheelbase | 2860 mm 112.6 in. |

| Pump capacity | 96.1 L/min 25.4 gpm |

| Rated pressure | 195 bar 2828 psi |

Loader

| Base weight | |

| Leveling configuration | Mechanical Self Leveling (MSL) |

| Bucket used | Materials 2450 mm Materials - 85 in. |

| Bucket weight | 352 kg 776 lb |

| Lift capacity at full height | Measured at pivot (U) 2065 kg 4553 lb Measured at 800 mm ahead of pivot (V) 2240 kg 4938 lb |

| Lift capacity at 59 in. (1500 mm) | Measured at pivot (W) 3420 kg 7540 lb Measured at 800 mm ahead of pivot (X) 3280 kg 7231 lb |

| Boom breakout force | Measured at pivot (Y) 4793 kgf 10567 lbf Measured at 800 mm ahead of pivot (Z) 4395 kgf 9689 lbf |

| Bucket rollback force capacity | At maximum height (VV) 3641 kgf 8027 lbf At 59-in. (1500-mm) lift height (XX) 4599 kgf 10139 lbf At ground-level line (ZZ) 4640 kgf 10229 lbf |

| Dimensions | Maximum lift height (A) 4650 mm 183.1 in. At full height - bucket level(B) 4465 mm 175.8 in. At full height - bucket dumped (C) 3820 mm 150.4 in. |

| Overall length (I+F), ft (m) | 5.6 m 18.7 ft |

| Overall height in carry position (J) | 2.4 m 7.8 ft |

| Digging depth (H) | 150 mm 5.9 in. |

| Reach | At maximum height (D) 820 mm 32.3 in. At ground level - bucket level (F) 2790 mm 109.8 in. |

| Bucket angle | Dump angle, degrees (E) -58.9 degree (angle) Rollback angle, degrees (G) 42 degree (angle) |

| Cycle times | Loader raise, seconds 5 seconds Loader lower, seconds 5.5 seconds Bucket dump, seconds 3.5 seconds Bucket rollback, seconds 4 seconds |

Additional information

| Date collected |