Key Features

- Urethane roll conditioner available

- Cutting platform is gear-driven

- Adjustable gauge shoes

- Flotation tires

Features

Clevis hitch

Clevis hitch

The clevis hitch is in base equipment on the 630 and 635 Mower-Conditioners. This design attaches directly to the tractor drawbar for operator convenience. The heavy-duty clevis design provides a strong attaching point to the drawbar.

For added convenience, the hitch pin retaining bracket can also be used to store the power take-off (PTO) shaft when the machine is not attached to the tractor.

The clevis hitch is designed to be towed by a tractor only and includes a screw jack and safety chain.

Turn limiters may be required to prevent powerline damage if the hitch point of the tractor is beyond the rear drive wheels of the tractor.

1000-rpm overrunning clutch

1000-rpm overrunning clutch

An overrunning clutch is located near the platform gearcase on all models. This design enables free rotation of the tractor hookup to make attachment to the tractor easier.

On 540-rpm machines (optional on the 630 model only), a slip clutch is incorporated into the overrunning clutch to provide protection to the platform. No clutch is required on 1000-rpm machines due to the reduced torque loads.

Drawbar equal-angle hitch

Drawbar equal-angle hitch

Drawbar extension

Drawbar extension

The drawbar equal-angle hitch is optional equipment on the 630 and 635 Mower-Conditioners. This hitch option includes:

-

Ball-joint hitch—to be installed on the mower-conditioner tongue

-

Tractor hookup

-

Drawbar extension—to be installed on the tractor drawbar and adjustable with one wrench

The drawbar equal-angle hitch is designed to be towed by a tractor only and includes a screw jack and safety chain.

Turn limiters may be required to prevent powerline damage if the hitch point of the tractor is beyond the rear drive wheels of the tractor.

1000-rpm overrunning clutch

1000-rpm overrunning clutch

An overrunning clutch is located near the platform gearcase on all models. This design enables free rotation of the tractor hookup to make attachment to the tractor easier.

On 540-rpm machines (optional on the 630 model only), a slip clutch is incorporated into the overrunning clutch to provide protection to the platform. No clutch is required on 1000-rpm machines due to the reduced torque loads.

Swivel hitch

Swivel hitch

For added maneuverability, the 630 and 635 Mower-Conditioners offer an optional rockshaft swivel hitch. Turn limiters are not required with the swivel hitch.

The swivel hitch is available in a 1000-rpm power take-off (PTO) only. It attaches to the lower lift arms of a Category 2 or 3N 3-point hitch with or without quick-hitch.

This option enables cutting square corners as well as making it easier to cut around field obstacles. Tractor hookup U-joint angles remain constant for reduced driveline noise and vibration in turns.

NOTE: If the platform is to be maneuvered while under power, it is recommended the rear powerline with single constant-velocity (CV) U-joint be ordered.

A powerline support cable keeps the tractor hookup out of the dirt when detached from the tractor.

The parking stand allows quick and easy hookup. A down stop chain is also included which limits the travel of the rockshaft to help prevent implement driveline damage.

1000-rpm overrunning clutch

1000-rpm overrunning clutch

An overrunning clutch is located near the platform gearcase on all models. This design enables free rotation of the tractor hookup to make attachment to the tractor easier.

Rotary cutterbar

Rotary cutterbar

The rotary cutterbar is designed and built by John Deere. Large oval disks with free-swinging knives are used to cut the crop.

All cutting disks are the same and are computer-designed for improved wear and cutting performance.

Cutting disks are made of high-strength, austempered steel to ensure the steel is thoroughly and evenly tempered for good wear characteristics.

The disks rotate to give a knife-tip speed of 307 km/h (191 mph) for clean cutting.

The knives are free-swinging to reduce damage if a solid object is struck, and they are reversible to double the useful life.

The knives are removed at the front of the cutterbar for convenience.

Wear caps

Wear caps

Wear caps

Made of austempered, heat-treated, ductile steel for excellent wear characteristics, wear caps are installed on each end of the cutting disks (except on the end disks where crop accelerators are used) to increase the wear life of the cutting disks and knife-bolt nuts.

Wear caps are open on the end to prevent debris from packing in close to the nut, making hardware and knives easier to change.

Modular cutterbar

Modular cutterbar

John Deere's patented design cutterbar is made from individual, diagonal-cut modules.

Serviceability is easy. Modules can be removed individually while leaving the cutterbar attached to the frame.

Made of high-strength, nodular iron castings, each module consists of two idler gears and one drive gear. The large-diameter idler gears transmit power from module to module. The idler gears turn at a relatively slow speed for added durability.

The smaller-diameter pinion drive gear is used only to power the cutting disk. Power is not transmitted from one cutting disk to another except through the large-diameter idler gears.

The modules are interchangeable. Disk rotation is determined by the position of the quill (A). There is a rubber oil seal between each cutting module.

Tough enough for a three-year cutterbar warranty

The durable John Deere cutterbar comes standard with a three-year warranty on all 600 and 800 Series Mower Conditioners. This warranty covers all internal drive components, such as idler and pinion gears. Wear components, such as knives, wear caps, and shear hubs are not included in the warranty.

Gauge shoe

Gauge shoe

Steel runners are located under each disk. Right-hand and left-hand adjustable gauge shoes further protect the cutterbar.

The half-moon shaped disk protectors extend past the cutterbar module to protect the cutting disk.

The disk protectors are made of heat-treated boron steel, whose material characteristics are very similar to spring steel. Resistance to bending is nearly three times greater than molded ductile iron.

Knives rotate close to the disk protectors to give a good shearing action and help to keep the cutterbar clean.

Shearhub

Shearhub

Each cutting disk is attached to a driver (shearhub) on the splined pinion gear. The driver has part of its splines removed so it will shear if the cutting disk receives a severe impact.

The shear strength of the driver is designed to be just slightly less than that of the pinion gear.

Power to the disk is interrupted when the driver shears to protect the internal components of the cutterbar.

Damage is limited to exposed components and does not require disassembly of the cutting modules.

U-joint

U-joint

Power is transmitted through a U-joint to the first cutting disk.

The U-joint attaches with four bolts to the driver on the first cutting disk. No special tools are required to remove the first cutting disk.

The torque for attaching bolts is the same as for attaching the disk to the driver (149.1 Nm [110 lb-ft] compared to the 339 Nm [250 lb-ft] required to attach the driver to the pinion gear).

Impeller conditioner

Impeller conditioner

Impeller conditioning is standard equipment on all John Deere mower-conditioners.

Proper conditioning in a wide range of crops can be achieved when the conditioner is properly adjusted.

The impeller conditioner works well in legumes, especially alfalfa and most all-grass crops. Impeller conditioners are not recommended for thick-stemmed or cane-type crops, such as sudan or sudex, or crops over 1.5 m (5 ft) tall.

How an impeller conditioner works:

1. As hay is cut by rotating knives, tines pick up the plants and carry them through the machine:

- 33 V-shaped tines are on the 625 Mower-Conditioner; 45 V-shaped tines are on the 630 and 830 Mower-Conditioners; and 57 V-shaped tines are on the 635 and 835 Mower-Conditioners.

- Tines are free swinging to reduce damage to the conditioner if rocks or other solid objects are struck.

2. As the plant passes through, it rubs against the conditioning hood (A) and other plants:

Scuffing action removes the waxy surface from the stem of the plant to allow for faster evaporation of moisture.

Impeller hood crank handle

Impeller hood crank handle

Impeller hood position indicator

Impeller hood position indicator

- The conditioner hood opening is adjustable to accommodate various crop volumes.

- The crank handle allows an infinite number of adjustments between the minimum and maximum conditioning levels. The closer the hood is to the tines, the more aggressive the conditioning.

- A conditioner position indicator provides an easy reference point to control the degree of conditioning.

630 Mower-Coonditioner (shown with shields removed)

630 Mower-Coonditioner (shown with shields removed)

3. The speed at which the tines rotate will also affect the degree of conditioning. Two impeller speeds can be achieved by interchanging the upper sheave (A), located under the shield, and the lower sheave (B).

- With the sheaves in the position shown, the impeller turns at 870 rpm; this is ideal for grasses.

- If the sheaves are reversed, the impeller turns at 630 rpm; this is ideal for legume crops.

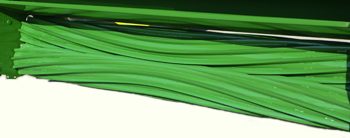

Urethane rolls

Urethane rolls

The 630 and 635 Side-Pull Mower-Conditioners and the 830 and 835 Center-Pivot Mower-Conditioners are available with a urethane roll conditioner.

The urethane roll conditioner works well in legumes, especially alfalfa, and most all-grass crops.

In general, roll conditioners are better suited for thick-stemmed, cane-type crops and crops more than 1.5 m (5 ft) tall.

Molded urethane rolls are formed by a cool molding process that does not distort or warp the steel core of the roll:

-

This process ensures the rolls are straight and cylindrical, so they can be accurately spaced close together for uniform conditioning along the length of the roll.

An intermittent recessed cleat design gives more crimping edges for greater pressure per square inch, which results in superior conditioning and faster crop drying.

Shields removed for illustration purposes

Shields removed for illustration purposes

Power is distributed by the platform and conditioner drive gearboxes:

-

Gearbox uses heat-treated, steel-forged spur gears for added strength.

-

Drive gears operate in a sealed environment to prevent excessive wear or contamination.

-

Telescoping drivelines ensure positive drive.

-

Spur gears have two to three teeth intermeshing at all times for a smooth, positive drive.

Handle for forming-shield adjustment

Handle for forming-shield adjustment

Forming shields are easily adjusted to control material flow. This allows the operator to match the windrow width to harvesting requirements.

Handle for swathboard adjustment

Handle for swathboard adjustment

A swathboard is in base equipment for additional control of the windrow formation (for 630 and 635 Mower-Conditioner models only).

Windrow width* is as follows:

| 625 | 78.7 cm to 149.9 cm (31 in. to 59 in.) |

| 630 | 88.9 cm to 198.1 cm (35 in. to 78 in.) |

| 635 | 99 cm to 238.8 cm (39 in. to 94 in.) |

*Depending on crop conditions.

Close-up of V10 steel conditioning rolls

Close-up of V10 steel conditioning rolls

The V10 steel conditioner rolls feature 10 angled flutes arranged in a chevron pattern, or V-pattern, along the length of the steel core.

Steel rolls offer improved wear life over urethane rolls, particularly in adverse crop conditions.

Advantages of the V10 conditioner roll over the previous straight flute design are as follows:

- More crimping edges for improved conditioning

- Improved feeding

- Improved windrow formation

Wide swath kit

Wide swath kit

The wide swath kit is a factory-installed option for the 630, 635, 830, and 835 Mower-Conditioner models.

When equipped with an impeller conditioner, the kit consists of a redesigned, base swath board and four (3.0-m [9.8-ft]) or six (3.5-m [11.5-ft]) steel vanes bolted to the bottom of the swath board.

On roll conditioner machines, the kit also comes with a redesigned, base swath board but has six (3.0-m [9.8-ft]) or eight (3.5-m [11.5-ft]) steel vanes.

When the forming shields are fully open, this kit will increase windrow width up to 25 percent over the base configuration of the machines.

Key Specs

| PTO speed | 540 or 1,000 rpm |

| 1000 rpm 1-3/8 in. PTO | 48-112 kW 65-150 hp |

| 1000 rpm 1-3/4 in. PTO | |

| Powerline type | Double-telescoping Grob spline |

| Standard hitch | Clevis |

| Optional hitch | Ball joint equal angle hitch |

| Hydraulic pressure required | 13,790 kPa 2,000 psi |

| Cutterbar - cutting width | 3 m 9.75 ft |

| Number of disks/knifes | 6 12 |

| Transport width | 3 m 9.75 ft |

Power requirements

| PTO speed | 540 or 1,000 rpm |

| 540 rpm PTO | |

| 1000 rpm 1-3/8 in. PTO | 48-112 kW 65-150 hp |

| 1000 rpm 1-3/4 in. PTO | |

| Powerline type | Double-telescoping Grob spline |

Tractor equipment

| Tractor connection | |

| Standard hitch | Clevis |

| Optional hitch | Ball joint equal angle hitch Rockshaft swivel hitch |

| Hydraulic pressure required | 13,790 kPa 2,000 psi |

| Hydraulic connections |

Cutterbar

| Type | John Deere |

| Cutting width | 3 m 9.75 ft |

| Cutting height | Without extension: 28 to 98 mm 1.1 to 3.7 in. |

| Number of disks | 6 |

| Number of knives | 12 |

| Bolted knives | |

| Disk speed | 2,650 rpm |

| Knife tip speed | 307 km/h 191 mph |

| Disk drive | Gear |

| Lubrication | Hy-Gard oil |

| Oil reservoir capacity | 7 L 7.4 qt |

| Cutterbar oil check | Drain plug |

| Cutterbar angle | Adjustable |

| Angle adjustment | Mechanical or hydraulic |

| Angle range | |

| Cutterbar protection | Shear hub |

| Adjustable gauge shoes | Yes |

| Suspension system |

Impeller conditioner

| Width | 1,854 mm 73 in. |

| Diameter | 594 mm 23.4 in. |

| Tines type | V-tines |

| Number of tines | 45 |

| Number of speeds | Two |

| Drive | 3-V powerband belt and sheaves |

| Conditioner hood | Infinite adjust, single hand crank |

| Wide spread |

Rolls conditioner

| Width | 1,854 mm 73 in. |

| Diameter | 254 mm 10 in. |

| Type of material | Urethane |

| Design | Recessed cleat |

| Speed | 664 rpm |

| Drive | Telescoping shaft |

| Windrow width |

Dimensions

| Transport width | 3 m 9.75 ft |

| Overall length | |

| Transport length | With equal angle tongue: 6.2 m 20.5 ft |

| Weight, roll conditioner | |

| Weight, impeller conditioner | 2,130 kg 4,696 lb |

| Standard tires | Standard: 11L-15 Optional: 31x13.5L 15 |

General

| Are wrenches required for adjusting? |

Additional information

| Date collected |